How can 5G accelerate manufacturing?

With its increased speed, higher bandwidth and lower latency, fifth-generation wireless cellular technology, or 5G, has the potential to be a key enabler and accelerator of the next generation of smart manufacturing. Some advantages of this communications technology for industrial applications include:

- Higher Bandwidth – modern IIoT gateways and distributed edge compute architectures are creating an explosion of valuable plant data and 5G networks are ideally suited to keep up with this data deluge

- Lower Latency – allowing devices to communicate more quickly and reliably is especially important for machine-to-machine communications to function effectively

- Greater Device Density – 5G has the potential to connect to more devices, up to 1 million per km2, critical for a factory full of sensors

- Device self-registration – time and costs associated with deployment, setup and commissioning will be greatly reduced

- Increased Security – cellular networks are more difficult to hack than standard WiFi implementations

- Fewer Cells – cellular signals can travel farther than WiFi, requiring fewer cells vs access points in an equivalent network

- Lower Power – the NR (New Radio) specifications have the potential to reduce power consumption by up to 100x

When will 5G accelerate manufacturing?

But the ultimate future of widespread 5G deployments in factories is not necessarily a foregone conclusion. Initial investments in acquiring private spectrum, purchasing hardware and the associated costs with learning and managing a new technology will be significant, especially in the early stages. It will require a total workforce transformation.

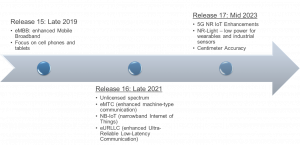

And while the initial rollout of 5G will be focused on an enhanced mobile broadband (eMMB) experience – mostly targeted at cell phones and tablets, the IIoT enhancements necessary for manufacturing deployments are not scheduled for the next “R-16” release. This includes the ability to use unlicensed spectrum, machine communication protocols (like eMTC enhanced machine-type communication and NB-IoT narrowband Internet of Things) and the lower latency improvements (eURLLC enhanced Ultra-Reliable Low-Latency Communication) will not be available until late 2021. And the enhancements to the 5G radio for low power sensors and wearables is not expected until mid-2023. The transition to 5G is truly a journey and will not happen overnight.

What about technology we already have?

Standard WiFi is not going away either. Newer technologies are on the horizon, offering improvements over existing wireless infrastructures. Following the well-known 802.11ac WiFi standard, the next generation will technically be 802.11ax, but will be known as WiFi 6. WiFi 6 will be up to four times faster in device-dense areas and offer much greater bandwidth than its predecessor.

There is no shortage of interest and excitement around 5G for manufacturing, but the debate on its advantages vs WiFi will only intensify as the next generation WiFi 6 is released. Ultimately the market will decide which is the preferred technology to use, and most likely it will be a hybrid combination of the two. In any case, smart manufacturers know that this next generation of wireless connectivity will be enabled and accelerated by a modern infrastructure that includes distributed compute architectures to support the significant data streams being created.

No matter the direction, Dell Technologies can help with the transition to whatever the wireless connectivity future holds. Enabling the transformational business outcomes promised by the IIoT will require a next generation digital infrastructure that only the Dell Technologies portfolio of companies and solutions can provide to build a truly integrated, converged, future-proof solution for all industrial customers.