In any industry that operates “machinery” such as manufacturing, transportation, construction, or any machine-heavy field, downtime and shrinking MTBF (mean time between failures) are the enemies, topped only by outright system failure. All three greatly increase overhead, and, combined with crisis maintenance, can result in significant losses for companies that need to be operating smoothly. How can organizations better handle their assets and ensure that operations are functioning and production is intact?

The answer is predictive maintenance: the shift in maintenance practices from reactive to proactive, increasing productivity and reducing downtime. The benefits — lower costs, better-functioning machines, and consistent production and delivery — are obvious, but getting there can be challenging. IT can help the operations department by providing it with predictive analytics, whereby operations can collect and analyze information to identify risks and opportunities and ensure that predictive maintenance is a reality.

Predictive Analytics: The Key to Proactive Maintenance

The value of predictive analytics is that it empowers maintenance and operations decision-makers to “see” when an asset will need intervention well in advance of its failure. Predictive analytics provides the highest possible visibility of an asset by collecting and analyzing various types of asset data. To obtain excellent predictive maintenance, organizations must bridge the gap between information technology and operations technology. The way to do this is with the ecosystem of sensors, devices, and equipment known as the Internet of Things (IoT). Companies can transmit and receive IoT data for tracking, analysis, and action. But to do so, they need their IT organizations to manage, at a viable cost, the global deployments of technology that are necessary to enable 24/7 access to IoT data. In fact, some companies are already doing so: According to a recent survey report, “best-in-class” companies are increasingly using IoT to implement predictive maintenance models that address their top operational challenges to improve their use of assets.1 This report revealed that the benefits of predictive maintenance practices include:

- Reduced unplanned downtime by 3.5% – Amount of unscheduled downtime against total availability

- Improved overall equipment effectiveness (OEE) to 89% – Multiplying availability, performance, and quality

- Reduced maintenance costs by 13% year over year – including time and personnel

- Increased return on assets (RoA) by 24% – Profit earned from equipment resources through improved uptime

A Comprehensive Dell Solution for Predictive Maintenance

While IoT is transformative, sensors alone do not transform operations, and data points without connectivity do not transform business activity. It takes expertise and a holistic perspective to put together a solution that embraces all of the benefits of predictive maintenance. It was with these benefits in mind that Dell collaborated with SAP on a Dell SAP IoT solution that brings predictive maintenance quickly to life in an operations environment.

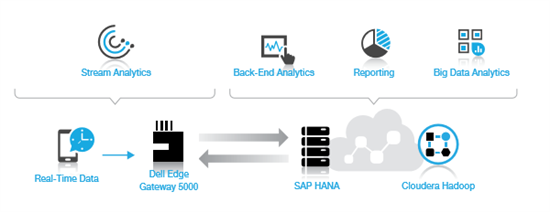

The solution combines Dell Edge Gateways for IoT with SAP HANA and SAP HANA Vora for real-time analytics and Cloudera Hadoop for unstructured data storage. SAP HANA enables the move from reactive to predictive maintenance and service by analyzing large volumes of operational and transactional data. It provides in-depth insight into asset history and trends to help predict maintenance and service needs.

Dell Edge Gateway 5000, part of the Dell Edge Gateways for IoT series, supports best practices for predictive maintenance in several ways. It is an industrial-grade, scalable solution that works with a variety of critical protocols, data sources, and data types to enable the collection of the predictive data you need. To support the predictive analytics powered by SAP HANA, Dell Edge Gateway 5000 hosts SAP SQL Anywhere, which connects to other databases via Mobilink. This comprehensive remote data management system allows for full data synchronization to a consolidated database, even in large and complex environments. It also interfaces with OSIsoft for integration with SAP HANA.

At the core, SAP HANA, deployed on a Dell PowerEdge R930 HANA Appliance, analyzes equipment performance data and uses predictive algorithms to forecast future performance failure. It uses predefined models to automate decision making and make maintenance recommendations. With the help of SAP HANA Vora, it enables data analytics on unstructured sensor data, combined with data from enterprise sources, to identify patterns that help predict failures with ample time to prevent them.

Cloudera Hadoop enables distributed storage and distributed processing of very large data sets on a clustered platform. In this case, it acts as a persistent storage layer for the streaming of unstructured equipment sensor data. Dell’s Hadoop platform is thoroughly tested and validated for use in the acceleration of these big data deployments.

Realizing the Potential

True predictive maintenance based on IoT has the potential to transform the industrial world — and organizations that understand and use this technology will have a competitive edge. Using IoT to link operations’ rich information stores with IT’s analytical power will be the key to gaining this competitive edge, and Dell’s predictive maintenance solutions for SAP systems now makes this more accessible.

For more information on best practices for predictive maintenance, see Dell | SAP IFM Predictive Maintenance Reference Architecture and the Dell Predictive Maintenance Blueprint “Six Steps to Using the IoT to Deliver Maintenance Efficiency”, and for more information about Dell innovative solutions for SAP systems, please visit the Dell SAP website or contact the Global SAP Center of Excellence – Dell’s Think Tank for SAP.

1 Aberdeen Group, “Analytics for the Internet of Things: Who, How, and Why?” (2015; http://aberdeen.com/research/11449/11449-rr-iot-analytics/content.aspx